The plain packaging policy in Australia has transformed the global tobacco market. It was introduced in 2012 and has established a strict precedent that other countries are following. Exporters to Australia must comply with the highest standards. High-quality cigarette boxes are essential in this process. With stringent regulation and sound production, you can have long-term export success. The quality of australian cigarette boxes enables brands to compete with confidence without compromising on quality.

Australian Cigarette Packaging – Understanding Framework

Australia pioneered the introduction of legislation on plain packaging in an attempt to control the use of tobacco. This act standardized the packaging of cigarettes, making the packs less appealing. The policy removed the logos, exclusive colors, and ornamental finishes. The intention was obvious- to deter smoking by an ugly display. To exporters, these rules provided a rigid border. Packaging manufacturers were compelled to adjust their production to meet new expectations. The layout also makes all cigarette packs appear similar, regardless of the brand.

Regulatory Compliance: The Foundation of Export Success

Strict compliance is the main starting point of export-ready packaging. Pantone 448 C is dull olive-brown and is the only color to be used. This regulation does not allow brands to apply pleasing colors. Typography is also as strict. It is prohibited to use logos or graphic symbols; only the Lucida Sans font is allowed. Set rules also guide box formats. Rigid, rectangular flip-top boxes are the only legal ones. Packs, tins, or tubes of slides are prohibited. Moreover, metallic, metallic-glossy, or textured finishes are forbidden. These rules guarantee an easy market penetration in Australia.

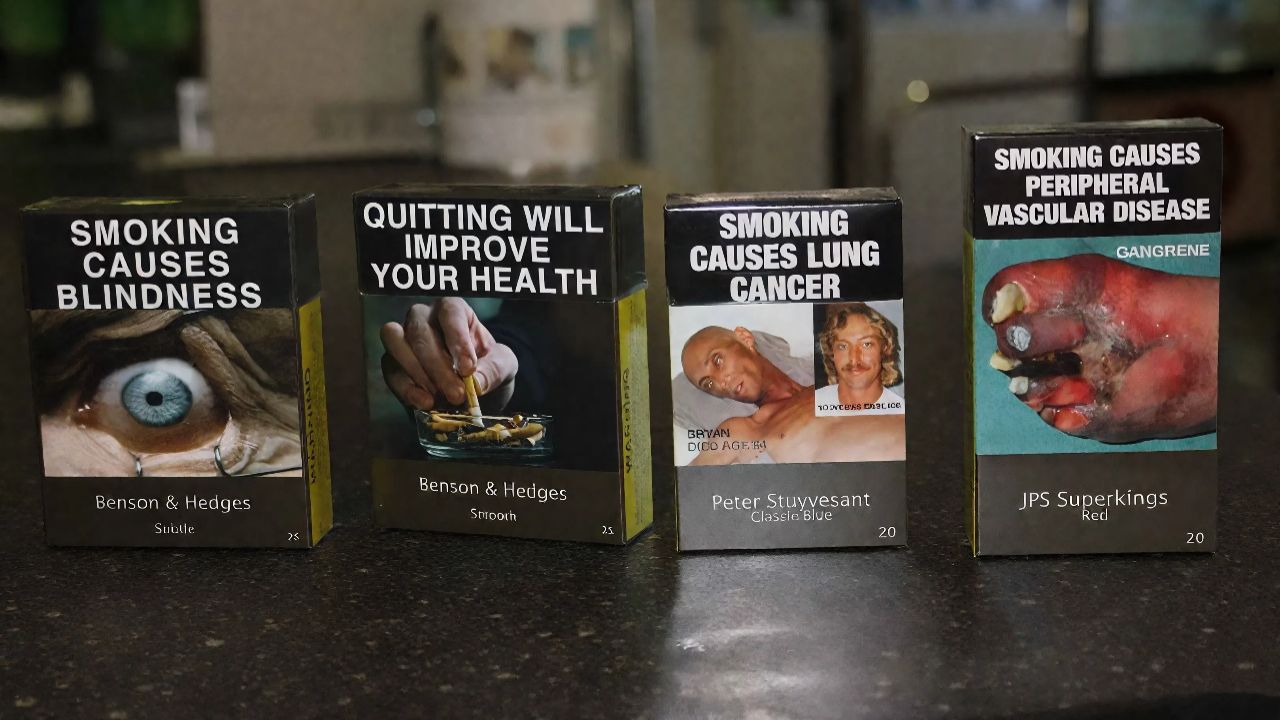

Health Warning Requirements and Their Impact on Packaging Design

Health warnings dominate most cigarette box designs in Australia. The images approved by the government should occupy 75 percent of the front and back. Yet these graphic warnings usually depict the harmfulness of smoking, such as cancer or lung disease. Side panels must contain specific details about the products and a quitline number. The upper seal should have a brief warning message, such as “Smoking kills.” These compulsory factors lower the space for the brand. Exports are not approved because they fail to meet these requirements. Exact compliance is the key to successful shipment.

The Importance of Material Quality in Premium Cigarette Boxes

Cigarette boxes are simple in design but have to be of premium quality. Long-distance shipping depends on durable materials. Rigid boards ensure the packs are received in the best condition. The range of design options is limited, but you can enhance the level of touch. A hard, yet smooth, substrate conveys professionalism. There is an increasing importance of sustainability. Good environmental responsibility is achieved through the use of high-quality, eco-friendly materials. The best substrates offer a lawful and commercial authority.

Advanced Manufacturing Standards for Export-Ready Packaging

Success in mass cigarette packaging is determined by consistency. Precision printing ensures that all packs comply with strict design requirements in Australia. Any slight difference is subject to rejection. High-level manufacturing technology contributes to the consistency of large-volume deliveries. Mass production requires quality assurance checks. The batches should be identical to the approved samples. This consistency spares exporters the expensive hassles of time loss. These standards ensure that your packaging is credible and compliant with the law.

Tailored Customization Within Legal Boundaries

It is possible to customize even the strict rules. Subtle differentiation is made possible through material selection. Sustainable boards with more strength are more valuable. The durability of the box may also boost consumer confidence. The alternative pack sizes offer a choice and also satisfy the flip-top rule. Designs are plain, but craftsmanship counts. Professionalism is demonstrated through clean finishes and precise cuts. This balance between compliance and quality will give your brand an edge in legal matters.

Logistics and Reliability in Global Export Success

Exporting cigarettes to Australia would not only need compliant packaging. Complete delivery in a timely and secure manner is crucial. International logistics relations ensure global transportation. Packaging should be resistant to different weather conditions and long transport distances. Box strength is tested by moisture, heat, and handling pressures. Secure packaging will ensure there is no damage and they will still maintain compliance. Good logistics with high-quality boxes ensure a successful export.

The Competitive Advantage of Premium Packaging in a Plain Market

Quality is your competitive advantage in a plain packaging market. All brands look the same on shelves. The difference lies in the longevity/regularity/craftsmanship. Suppliers who provide quality, conforming items are appreciated by retailers. Regulators trust manufacturers with a history of accurate compliance—exporters with an emphasis on high quality gain a better reputation in foreign countries. Despite the lack of visual branding, effective packaging conveys trust.

Conclusion

High-end cigarette boxes still dominate the Australian export market. There are three pillars of success: compliance, quality, and logistics. Adherence to such regulations as Pantone 448 C and health warnings provides eligibility. Professional value is added by using durable and sustainable materials. Efficient production and distribution protect uniformity and supply. You can be confident about entering Australia with such expert partners as Ruenfo. Ruenfo focuses on non-insurgent, conforming, quality packaging that is customized to meet stringent legislation. Premium quality, as long as it is within the confines of the law, will guarantee your export success.